Ball Mill Feed Liner. Ball Mill Feed Liner - China Manufacturers Factory Suppliers With advanced technologies and facilities strict high-quality handle reasonable rate superior services and close co-operation with prospects we are devoted to furnishing the best price for our customers for Ball Mill Feed Liner Wear Resistant Plate Sure Alloy HardplateHardfacing Wear.

Inlet Feed Chute Systems Fundiciones Estanda

Email protected Lubrication Technologies Inc.

. The criterion used for selection was the effective length of dryer. Design Liners for inlet chute cement mill fl ball mill for cement grinding the fl ball mill is designed for in the mill inlet chute 183m x 274m 6 x 9 125 hp feed how to working in cement mill Cement mill - Wikipedia A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement. Chute design for coal - f1clubdeinzebe.

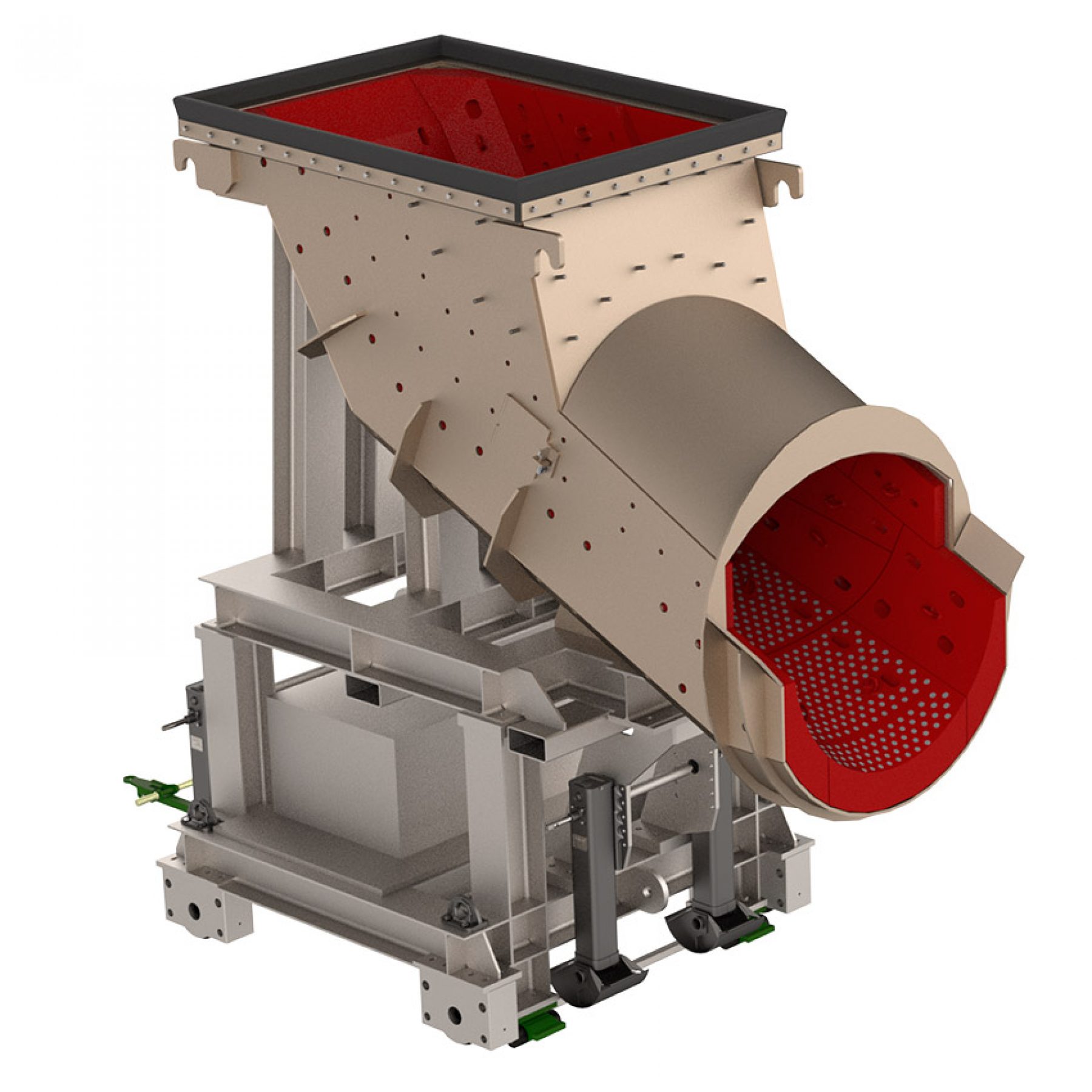

The best ball mill for russia 1500x3000- ball mill feed chute design wikipedia the best ball mill for russia 1500x3000 Ball Mills. The production capacity of the ball mill is determined by the amount of material required to be ground and it must have a certain margin when designing and selecting. The present work aims to design and analysis of Ball mill inlet chute along with the truck assembly for Roller press circuit UMS Unidan Mill S type FLS Ball mill which are used in the Cement industry for grinding clinker material.

The reason for cement mill inlet chute material inlet chutes for cement mills cement ball mill inlet feed chute design FL ball mill for cement grinding Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker gypsum and dry or moist additives to any type of cement. Fuller-Traylor SAGAG Mills range in size from 43m through 122m in diameter with powers as high as 28000 kW. Traditionally mills are lined with either cast high chrome manganese or rubber liners and even though mill chutes may have similar lining materials applied these are not always sufficiently robust to counter the excessive wear caused by.

The influence of the flow properties and chute flow dynamics in selecting the required geometry to minimise chute and belt wear at the feed point will be highlighted. We discuss the types of ball mill the basic principles of the ball mill how it works the details of design including equations for optimum dimensions in all cases some manufacturers for the ball mill and estimation of the cost the ball mill. This Design Of SAG Mill Feed Chute Lasted 9 Months Seeing 90000 TPD It Is 600 Brinell Chrome Steel With The Big Liners On The Bottom Of The Chute You Need To Get A Chevron Cast Into The Top To Push The Feed Out To The Sides For The First Little While And Then As The Chevron Wears It Will Start To Come Back Into The Centre This Will.

Design and analysis of ball mill inlet chute for roller press. Ad A Modular Design with all the Necessary Equipment. Chute flow patterns are described and the application of chute flow dynamics to the determination of the most appropriate chute profiles to achieve optimum flow is illustrated.

The Engineering Establishment tee is a trusted supplier of custom components for mining mills. Ball mill feed chute design wikipedia. Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach.

Inlet chute design of ball mill - inlet chute design of ball mill - SKY Machinery. Coal mill feed chute design with hot gas - grupporoyalit. WEST SPRINGFIELD MA 01089 Open in Google Maps.

Ball mill feed chute design wikipedia. Ball Mills - Whats New Radiation and Nuclear Chemistry Media Choice. When future tonnage is to be increased the SAG Mill can feed downstream ball milling to boost capacity.

Scoop Feeders for Ball-Rod Mills are made in various radius sizes. A methodology based on the DEM modeling was proposed to select the best feed chute design for large-scale industrial rotary dryers. There are many factors affecting the production capacity of the ball mill in addition to the nature of the material grain size hardness density temperature and.

The idea of this project is to design the feed chute for Roller press ball mill RPBM circuit with feed chute truck As for the diaphragm the outlet grate is provided with wear assembly to reduce the maintenance time as well as to resistant chromium cast steel grates bolted to the structural improve the production of cement. Then moves down the feed chute to what is the raw mills or. United Nuclear Scientific Equipment Supplies Products 1 - 10 of 10 United Nuclear.

Standard scoops are made of cast iron and for the 3 size a 13 or 19 feeder is supplied for the 4 size a 30 or 36 for the 5 a 36 or 42 and for the 6 a 42 or 48 feeder. The present mill inlet chute can be used for the two compartment ball mills. His 20 years of experience in the field is unmatched in sub-Saharan Africa.

Coal mill feed chute design with hot gas. The best overall Mill. Feed chute design of the Gol-E-Gohar pelletizing plant ball mill dryer to increase the throughput by increasing the dryer effective length.

1 Calculation of ball mill capacity. In ball mill applications balls are also fed through the transfer point or chute into the mill itself. Liner plates Rubber liners Chute liners liner plate for rollers liner plate for crushers Flotation spares Ceramic spigots Pulp lifters Wear parts.

Coal mill feed chute design with hot gas - ME Mining Machinery. Jan Lux heads up tee. Introduction Ball mill is an efficient tool for grinding many materials into fine powder.

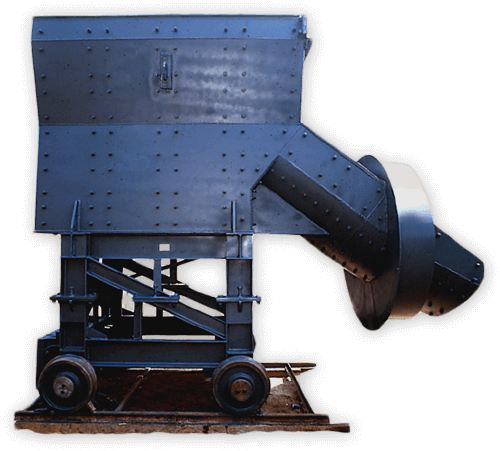

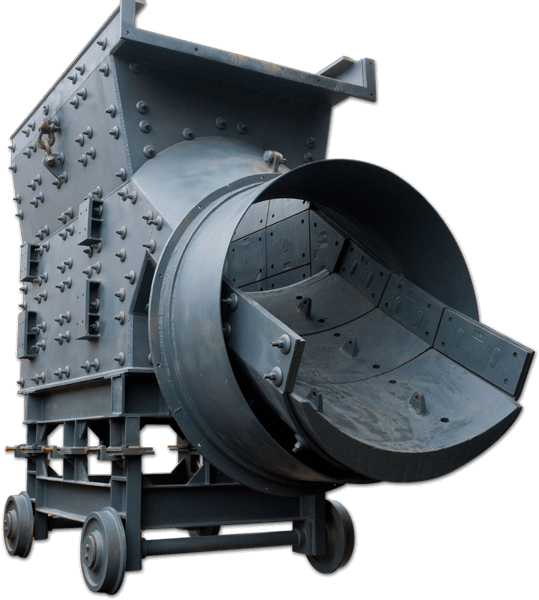

Ball Mill Retractable Feed Chute. Types of Mill Feed Chute. Ball mill feed chute design wikipediaremonty skowron.

CiteSeerX - Document Details Isaac Councill Lee Giles Pradeep Teregowda. The Unidan mill type UMS is designed for the grinding of clinker gypsum and dry Hot drying air enters through an insulated inlet with feed chute The grinding compartment has a classifying lining and a ball charge designed for grindingget price.

Sag Mill Feed Chute Design Long Life Wear Resistant

Sag Mill Feed Chute Design Long Life Wear Resistant

Sag Mill Feed Chutes Makuri Group

Sag Mill Feed Chute Design Long Life Wear Resistant

Absolute Material Control Key In Mill Feed And Scrubber Transfer Points

Outotec Expands Grinding Portfolio With New Equipment Transporter Reline Machine Solutions International Mining

0 comments

Post a Comment